Silverthin bearings are produced in the US and they successfully conform to the strict rules that have been set out under the Berry amendment. These bearings come in regular configurations, unsealed or sealed and they are minimum 40 inches in their diameter. The typical bearings are produced or stocked for meeting the short lead time requirements of customers. The special varieties of these bearings are manufactured and engineered using special coatings and materials for serving the requirements of the varied customer base. Bearing section and width in every series remain constant irrespective of the change found in the bore diameter.

It is important for you to understand that no single bearing is suitable for each single application. There are some applications that need special bearings for coping with the demands of harsh environments like cryogenic, high-ultra vacuum and cleanliness requirements of the pharmaceutical industry. Silverthin bearings are available in wide varieties of lubrication, materials and coatings combinations. The notable specifications of these bearings include:

- AISI 52100 vacuum degassed races bearing steel.

- Stabilized and hardened heat treatment to be used at 65 degrees to +250 degrees.

- AISI 52100, 440 C or ceramic calls.

- Reinforced with Seals Buna-N rubber metal

- ABMA standard of 26.2 with diametric clearance

- ABMA standard for preloads in 26.2

- These bearings are marked using lot code and part number and they also have the term “Silver” inscribed on the exterior diameter.

- Preservative oil should be used for cleaning agitation and immersion.

The Varied Uses of Silverthin Bearings

These bearings are very good at improving the efficiency of an equipment or a machine. From higher speed to greater reliability and accuracy, put simply these bearings help in increasing your build and profit on all the services that you offer to your customers. These bearings are also of good help in lowering operational costs of machinery leading to less recurrent services. One of the best things that make these bearings exclusive is that these bearings provide increased flexibility in design and reduced friction. It is only because of their shape and their size that these bearings are able to help in creating additional space and in saving weight. Starting from aerospace telescopes and medical equipment to ceiling fans and fridges, these bearings can easily be found in every mechanism involving movement. The bearings work on a very simple and convenient principle- objects seem to move better once there is a reduction in friction.

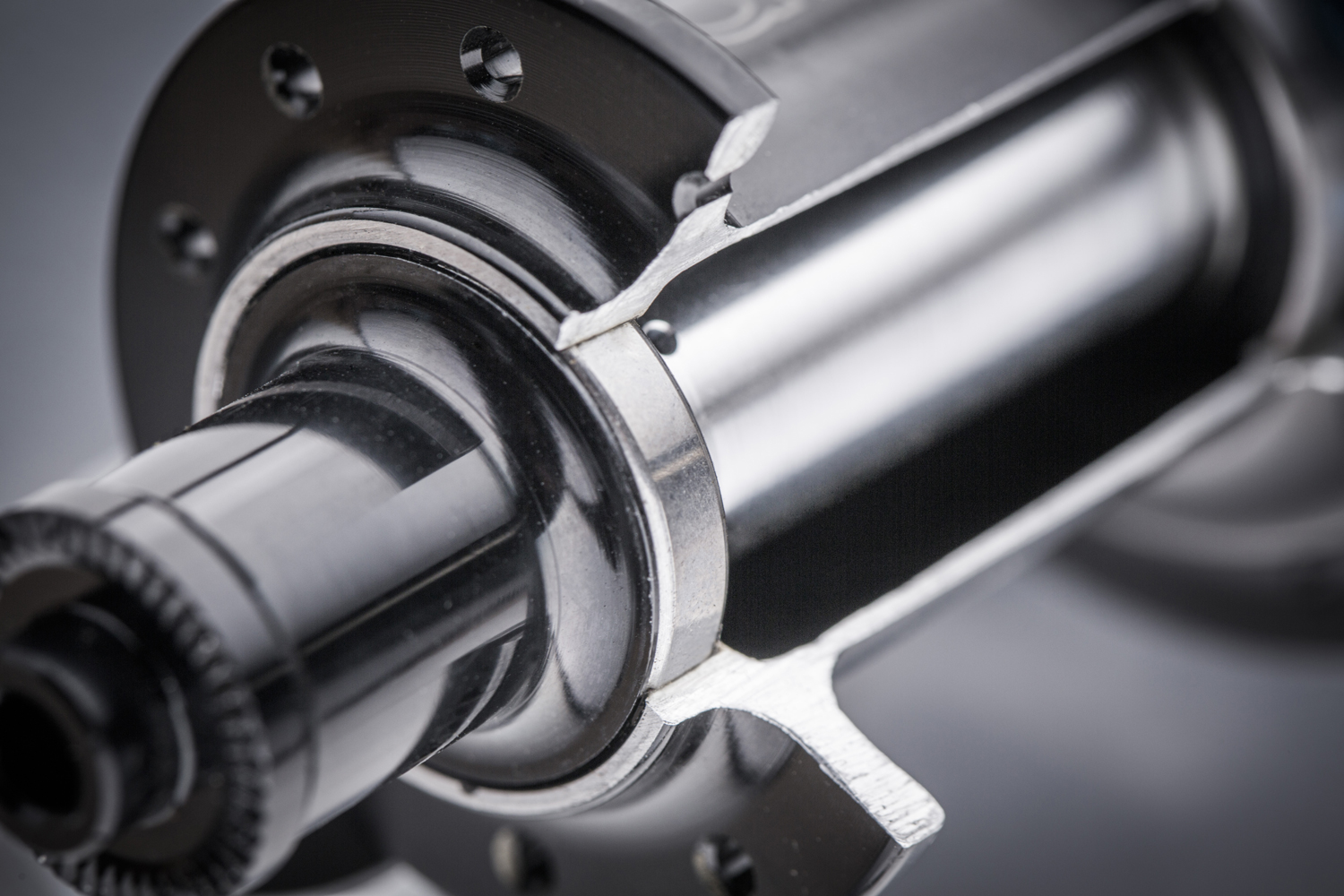

Installing a Silverthin Bearing

The installation procedure of this bearing is quite easy. If the bearing is being installed in a house, then proper pressure needs to be exerted on the exterior ring. On the other hand, if the bearing is being installed on a shaft, then pressure needs to be exerted on the interior ring. Most of these bearing varieties are open, meaning they do not have seals and therefore it is advisable to use a contaminant-free and a clean installation area for these bearings. These are some of the most important things that you need to bear in mind when working with a Silverthin bearing.